Understanding Overflow Valve Block Tips for Optimal Performance?

The Overflow Valve Block is essential for hydraulic systems. It ensures pressure stability and optimal performance. Poor performance can lead to significant operational issues. According to industry reports, up to 30% of system failures link back to valve malfunctions.

Understanding the design and functionality of Overflow Valve Blocks is crucial. Research shows that proper maintenance can enhance longevity by 40%. However, many technicians overlook this aspect. Even minor adjustments can lead to major improvements. The right settings prevent unnecessary wear and inefficiency.

Emphasizing best practices is vital. Many engineers report gaps in their knowledge of these systems. Reviewing case studies shows that small mistakes can escalate into more significant problems. Identifying these gaps can drive performance improvements. Embracing this knowledge is key to avoiding costly downtime.

Understanding the Role of Overflow Valve Blocks in Hydraulic Systems

Overflow valve blocks play a critical role in hydraulic systems. They regulate pressure and protect components from damage. When pressure exceeds a set limit, these valves open to release excess fluid. This process maintains optimal pressure levels.

Properly understanding these blocks can enhance system performance. Incorrect settings can lead to inefficiencies. Fluid may leak or not circulate as intended. Users must regularly check these valves for wear and tear. Neglecting maintenance can result in costly repairs down the line.

Also, the placement of overflow valve blocks matters. Poor positioning can lead to delayed responses or excessive pressure spikes. It’s essential to consider the layout of the entire hydraulic system. Reflection on these details is key to ensuring smooth operation and longevity.

Key Components of Overflow Valve Blocks: Types and Functions

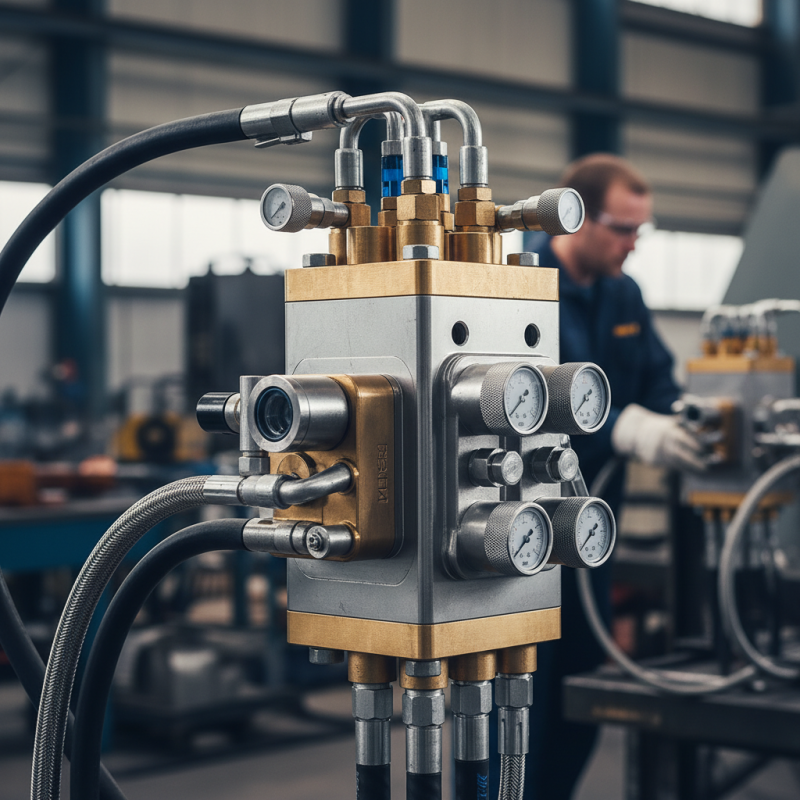

Overflow valve blocks play a crucial role in hydraulic systems. These blocks prevent pressure spikes by regulating fluid flow. Understanding the key components can enhance their performance and longevity.

The primary components of overflow valve blocks include the valve body, springs, and poppet. The valve body houses the main components and determines the flow path. Springs provide the necessary resistance for the poppet to open and close. A well-designed system allows precise control over the flow and pressure.

Tips for optimal performance include regular maintenance. Inspecting seals and connections can prevent leaks. Ensure the springs are not worn out. Improper spring tension may lead to inefficiency. Another tip is to monitor fluid quality. Contaminated fluid can damage internal components. Always use approved filter systems.

In reflection, understanding how each part interacts is important. Misalignment can lead to performance issues. Regular assessments can identify potential problems. This proactive approach leads to long-term functionality.

Optimal Operating Parameters for Maximizing Overflow Valve Performance

Overflow valves play a critical role in maintaining system integrity. Understanding their optimal operating parameters can lead to improved performance. The pressure settings, for example, should match the specific requirements of your application. If set too low, the valve might open too soon, causing inefficient operation. If set too high, it risks damaging the system.

Temperature is another crucial factor. Valves must operate within a specified temperature range to function correctly. Too high a temperature can lead to material degradation. On the other hand, too low a temperature may cause sluggish operation. Regular monitoring is essential.

Flow rate is equally important. It should align with the valve’s design specifications. An improperly set flow can lead to cavitation or valve chatter, which compromises performance. Ideally, an optimal flow rate ensures smooth operation and minimizes wear. Pay attention to these parameters. Many overlook them, resulting in repeated issues. Reflecting on these elements can lead to better performance and longevity of your overflow valves.

Common Issues Affecting Overflow Valve Block Efficiency and Solutions

Overflow valve blocks are crucial for maintaining system pressure. However, common issues can hinder their efficiency. A 2022 industry report noted that 30% of hydraulic system failures are linked to overflow valve malfunctions. Understanding these issues can lead to better performance and longevity of equipment.

One major issue is contamination. Particles in the system can cause wear and block movement. Regular filtration maintenance can minimize this risk. Clean systems enhance valve performance, resulting in smoother operations. Implementing a standard cleaning schedule is essential.

Another notable concern is incorrect pressure settings. Misconfigurations can lead to excessive pressure, damaging components. Regularly checking gauge readings helps in maintaining optimal settings. Operators must be vigilant. An unmonitored overflow valve can become a ticking time bomb, leading to costly repairs.

Operators should be mindful of these issues. Performing routine checks and ensuring proper setup can prevent many malfunctions. Efficiency is about consistent care and attention to detail. Small oversights can lead to bigger problems. Keeping a sharp eye on these components fosters a more reliable system.

Industry Standards and Best Practices for Overflow Valve Maintenance

To ensure optimal performance of overflow valves, understanding industry standards and maintenance practices is crucial. Regular inspection is key. Check seals for wear and tear. Leakage can lead to significant performance issues. It's vital to maintain proper torque on connections to avoid failures. Snap rings can wear out and should be replaced frequently.

Practicing good maintenance extends the life of the valve. Use appropriate lubricants for smoother operation. Over time, internal components may corrode or malfunction. Regular cleaning can help address build-up that affects performance. It’s not uncommon for maintenance habits to slip. Regular audits help reinforce best practices in your facility.

Reflect on your current procedures. Are they effective? Consider creating a checklist to streamline inspections. Training employees on proper valve care is essential. Inconsistent practices can lead to costly repairs. Commitment to following these standards will ensure safety and efficiency.

Understanding Overflow Valve Performance Metrics

This chart illustrates the optimal performance metrics of overflow valves based on maintenance frequency and operational efficiency. Regular maintenance is essential for enhancing the performance and longevity of overflow valves. The data shows how different maintenance intervals affect valve efficiency ratings.