How to Choose the Right Welded Wire Mesh for Your Project?

Choosing the right welded wire mesh for your project can be daunting. Each project has unique needs, making it essential to understand your options. Industry expert John Doe once said, "Selecting the proper welded wire mesh ensures durability and functionality." This insight highlights the importance of making an informed choice.

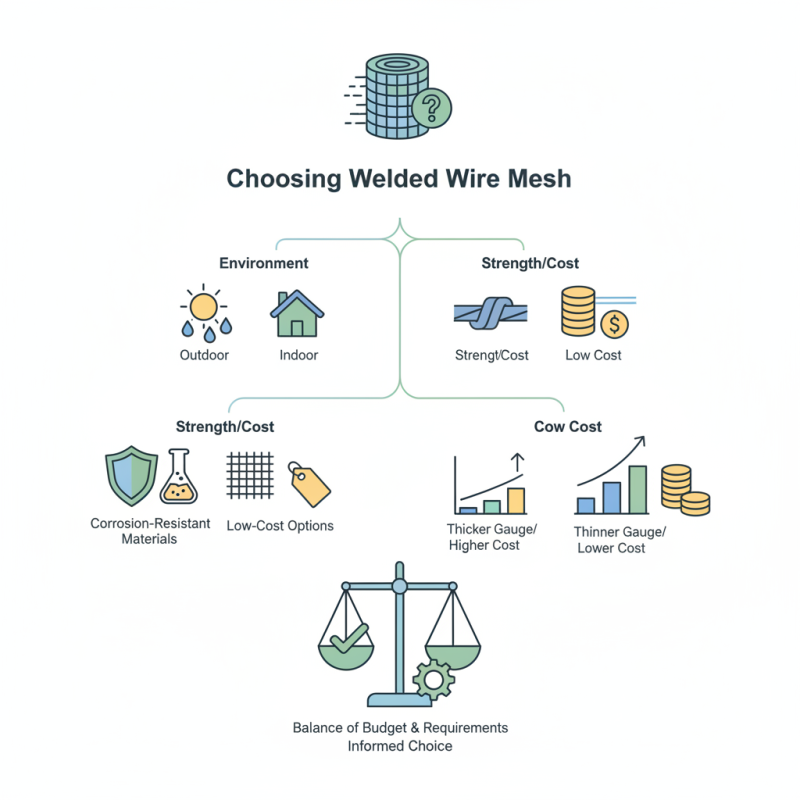

welded wire mesh comes in various sizes and materials. It might feel overwhelming when trying to decide which one fits your needs. Consider the environment where it will be installed. Corrosion-resistant materials may be necessary for outdoor projects. However, low-cost options could suffice for indoor uses.

Don't overlook the mesh's gauge. A thicker gauge can provide more strength but can also increase costs. Each project has its own balance of budget and requirements. Reflect on what matters most before finalizing your decision. Understanding these details can lead to a more successful outcome.

Understanding Welded Wire Mesh Specifications and Standards

When it comes to choosing welded wire mesh, understanding specifications is crucial. These specifications often vary based on the intended use. Look for wire diameter, mesh opening size, and material type. Different projects require different strengths and resistances. For example, a gardening project may need finer mesh, while a fencing job may require a sturdier option.

Tips: Always check the gauge of the wire. A lower gauge means thicker wire. Thicker wire offers better durability. Measure the spacing between wires to ensure it meets project needs. This attention to detail will save time and effort later.

Consider the coating on welded wire mesh. It can affect durability and appearance. Galvanized mesh typically resists rust, suitable for outdoor use. However, painted mesh offers a different aesthetic. It may chip over time. Think about the balance between aesthetics and functionality. Choosing the wrong type can lead to regrets later on.

Assessing Wire Gauge and Mesh Size for Your Application Needs

When choosing welded wire mesh, wire gauge and mesh size are crucial factors. The wire gauge refers to the thickness of the wire used. A higher gauge number means a thinner wire. According to industry reports, a 14-gauge wire is robust and suitable for fencing, while 18-gauge mesh is lighter for less austere applications. Selecting the right gauge ensures the durability of your project, which is vital for structural integrity.

Mesh size consists of the number of openings per inch. Typically, smaller openings provide greater containment and stability. For instance, a half-inch mesh size is useful for keeping small animals out. On the other hand, larger openings, such as 2-inch mesh, work well for applications like garden enclosures. It's essential to balance the need for strength with the specific requirements of your project.

However, overestimating the strength requirements may lead to unnecessary costs. Conversely, undersizing can result in failure during critical moments. Always reassess your project's demands against available options. This reflection may lead to better choices, ensuring both functionality and economy in wire mesh selection.

Evaluating Coating Options for Durability and Corrosion Resistance

When selecting welded wire mesh, coating options play a crucial role. Coatings enhance durability and corrosion resistance. Common choices include galvanized, PVC-coated, and powder-coated wires. Each type has its strengths and weaknesses.

Galvanized wire has a zinc layer for protection. It resists rust and increases lifespan. However, exposed areas can still corrode over time. PVC-coated options provide a vibrant finish and added durability. Yet, the coating can wear off, especially in high-friction areas. Powder coating offers a thicker layer but might crack under stress.

Evaluating your project's specific needs is essential. Consider the environment: is it humid or dry? Will the mesh face heavy wear? Balancing aesthetics with functional requirements is key. Sometimes the best choice isn't clear. Test samples if possible. Analyze performance before committing.

How to Choose the Right Welded Wire Mesh for Your Project?

| Mesh Type | Coating Option | Durability Rating | Corrosion Resistance | Applications |

|---|---|---|---|---|

| Stainless Steel | None | High | Excellent | Food Processing, Marine |

| Galvanized Steel | Hot-Dip Galvanized | Medium | Good | Fencing, Construction |

| Mild Steel | PVC Coated | Low | Fair | Agriculture, Landscaping |

| Fiberglass | UV Resistant Coating | High | Excellent | Industrial, Flooring |

| Vinyl Coated Wire | Vinyl Coating | Medium | Good | Decorative, Garden |

Exploring Applications and Industry Uses for Welded Wire Mesh

Welded wire mesh is versatile and widely used across various industries. It’s found in agriculture, construction, and security applications. According to industry reports, the global welded wire mesh market is projected to grow significantly by 2025. This growth is driven by increasing demand from the construction sector, which accounts for a substantial portion of the market share.

In agriculture, welded wire mesh protects crops and livestock from pests. Farmers use it to create enclosures and fencing. These materials are durable and withstand harsh weather conditions. Additionally, welded wire mesh plays a crucial role in concrete reinforcement. It ensures structural integrity in buildings and bridges. However, not all wire mesh products are created equal. The choice of wire thickness and spacing can impact the strength and effectiveness of the mesh.

Security applications often utilize welded wire mesh for fencing and barriers. This type of mesh acts as a deterrent against intrusions. Yet, there can be challenges in installation and maintenance. Improperly installed mesh can lead to vulnerabilities. Users need to consider these factors carefully when choosing wire mesh. Quality matters, but so does understanding specific project needs. Each application requires a tailored approach for optimal results.

Calculating Cost-Effectiveness for Large-Scale Welded Wire Projects

When tackling large-scale welded wire projects, calculating cost-effectiveness is crucial. Industry reports suggest that welded wire mesh can reduce costs by up to 30% compared to alternative materials. This significant saving comes from its strength and durability, which leads to less frequent replacements.

Keep an eye on hidden costs. Installation, transportation, and maintenance can add up over time. Some studies noted that overlooking these expenses could inflate overall costs by nearly 15%. Investing in the right type of mesh initially may seem high, but it pays off in longevity.

Tip: Look for local suppliers. They often offer competitive pricing and reduced shipping costs. Local sourcing can enhance project efficiency while supporting community businesses. Pricing can also fluctuate based on market demand, so be aware of current trends and prepare for potential changes.