How to Choose the Right Motorized Valve for Your Needs?

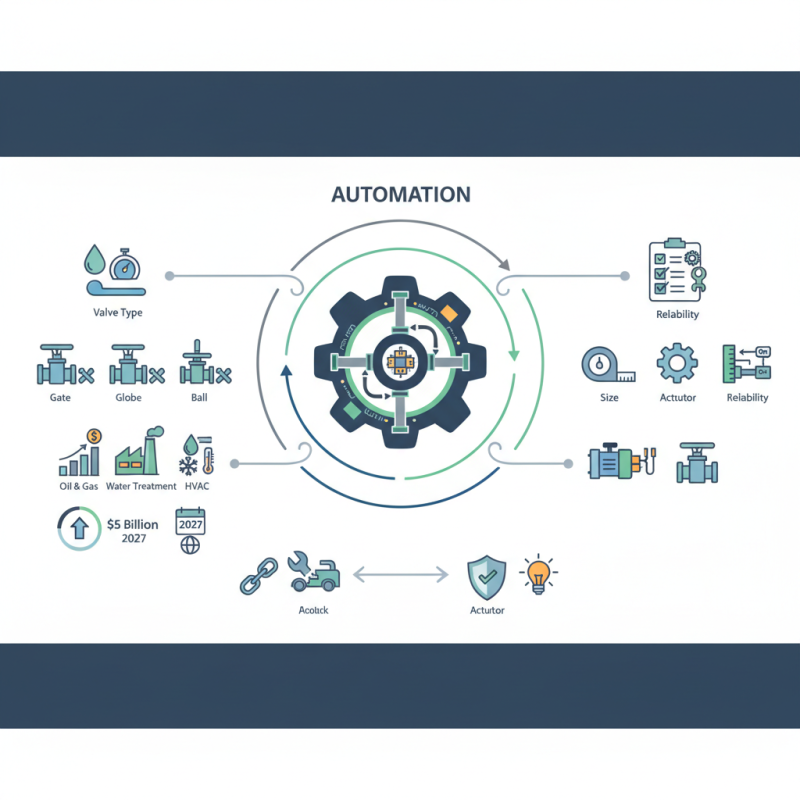

Choosing the right Motorized Valve is crucial for efficient system operation. The global motorized valve market size is expected to reach $5 billion by 2027, according to a recent industry report by *Global Market Insights*. This growth reflects the increasing adoption of automation in industries such as oil and gas, water treatment, and HVAC. Experts stress the importance of selecting the proper valve type, size, and actuator to ensure reliability and performance.

John Smith, a renowned engineer in the valve industry, notes, "Understanding specific application needs significantly impacts the selection of a Motorized Valve." His perspective emphasizes the need for careful consideration of factors such as fluid type and pressure requirements. Missteps in choosing the right valve can lead to costly operational issues.

Real-world applications illustrate this point. A manufacturing plant faced downtime due to incorrect valve selection. Their production halted while they corrected the mistake. Such scenarios highlight the risks of neglecting thorough evaluation. While choosing a Motorized Valve may seem straightforward, the consequences of a poor choice can be profound. Making informed decisions is essential to avoid potential drawbacks.

Understanding the Basics of Motorized Valves and Their Functions

Motorized valves play a crucial role in various industries. They control the flow of liquids and gases with precision. Understanding their basics is essential when selecting the right valve. Motorized valves rely on an electric motor to operate. This mechanism allows for remote control and automation, increasing efficiency.

According to a recent industry report, the global market for motorized valves is projected to grow by 7.5% annually from 2023 to 2030. This growth reflects the rising demand for automated solutions in energy, water management, and HVAC systems. Various types of motorized valves exist, including two-way and three-way valves. Each serves unique functions, influencing system performance.

However, choosing the right valve is not always straightforward. It requires careful consideration of flow rates, pressure ratings, and compatibility with existing systems. Often, users overlook the importance of matching the valve to the specific application. A mismatch can lead to inefficient operation or even damage. Engaging with detailed specifications and seeking expert advice can mitigate these risks.

Identifying Your Specific Needs for Valve Applications and Systems

Choosing the right motorized valve requires a deep understanding of your specific needs. It's essential to identify the fluid characteristics involved. For instance, water, gas, and oil all present different challenges. A recent industry study highlighted that incorrect material selection can lead to a 25% increase in maintenance costs over time.

Consider the pressure and temperature ranges in your applications. Motorized valves must withstand various conditions. Reports show that over 40% of valve failures result from exceeding these limits. It's crucial to specify the exact operating parameters when selecting a valve. This ensures longevity and reliability, especially in critical systems like HVAC or industrial processes.

Don’t overlook control requirements. Some systems need precise flow regulation. Others may demand quick on/off capabilities. Failure to match the valve's actuation type with your system’s control logic can lead to inefficiencies. In fact, studies suggest that improper control can decrease system performance by up to 30%. Always analyze your application needs carefully before making a final choice.

Evaluating the Different Types of Motorized Valves Available

When selecting a motorized valve, understanding the options is vital. Motorized valves come in various types, including ball valves, butterfly valves, and globe valves. Each type has unique characteristics that suit different applications. For instance, ball valves provide excellent sealing and are ideal for on/off control. In contrast, butterfly valves offer compact design and lightweight solutions for large volume flows.

Industry reports indicate that the global motorized valve market could reach over $4 billion by 2025. This growth reflects the increasing demand for automated systems across various sectors. However, choosing the right type requires careful consideration of fluid type, pressure, and temperature. For example, globe valves may excel in throttling applications, yet they can create significant pressure drops. This trade-off is crucial to evaluate based on performance needs.

Installation and maintenance also play a role in the decision process. Space constraints may dictate a compact design, like a butterfly valve. However, that could lead to inadequate performance in high-pressure systems. Each option presents its own set of challenges and benefits, making thorough evaluation essential. Balancing efficiency with functionality is key to optimal selection.

Factors to Consider When Selecting a Motorized Valve

Choosing the right motorized valve requires careful consideration of multiple factors. Start with the type of fluid being controlled. Different fluids, whether liquid or gas, may require specific valve designs. For example, corrosive fluids need materials that resist degradation. This is vital to ensure long-lasting performance.

Next, look at the size and flow rate. A too-small valve restricts flow, creating pressure drop. Conversely, a valve that is too large can lead to insufficient control. Sizing correctly can prevent costly system inefficiencies. Another detail to think about is the operating environment. Extreme temperatures or high pressures demand robust designs.

Control and automation features also matter. Do you need feedback systems? Is remote control a requirement? These can enhance functionality but may complicate your system. Consider if all your chosen features align with your operational needs. It’s essential to reflect on how each choice supports your overall goals.

How to Choose the Right Motorized Valve for Your Needs? - Factors to Consider When Selecting a Motorized Valve

| Factor | Description | Impact on Selection |

|---|---|---|

| Fluid Type | Consider the properties of the fluid (liquid, gas, corrosive, etc.) | Determines material selection and valve type |

| Pressure Rating | Expected pressure within the system | Affects durability and safety of the valve |

| Temperature Range | Operating temperature limits | Critical for material compatibility |

| Actuation Method | Electrical, pneumatic, or hydraulic | Impacts installation and operation complexity |

| Size and Flow Rate | Dimensions and capacity for flow | Determines valve size and appropriate cycle time |

| Control Requirements | Need for automation or manual control | Influences choice of actuator and control systems |

| Regulatory Standards | Compliance with industry standards and codes | Ensures safety and legality of installation |

| Budget Constraints | Total cost considerations for purchase and installation | Limits options based on financial resources |

Maintenance and Reliability Considerations for Motorized Valves

When selecting a motorized valve, maintenance and reliability are crucial factors to consider. These valves operate under various conditions, which can impact their longevity. Regular check-ups can help identify potential issues early. It's essential to be proactive rather than reactive.

Tips: Schedule maintenance at least twice a year. Regularly inspect seals and connections. Just a small leak can lead to bigger problems down the road.

Additionally, consider the environment where the valve will be used. Extreme temperatures or corrosive substances can affect performance. Choosing materials that can withstand your operating conditions is vital. Take the time to evaluate whether your chosen valve meets these requirements.

Tips: Use a maintenance log to track repairs and inspections. Documenting changes can prevent future mistakes. Don’t forget that even the best valves require attention over time. Regular maintenance can extend their lifespan significantly.