Why Choose a Rubber Pump Impeller for Your Industrial Needs?

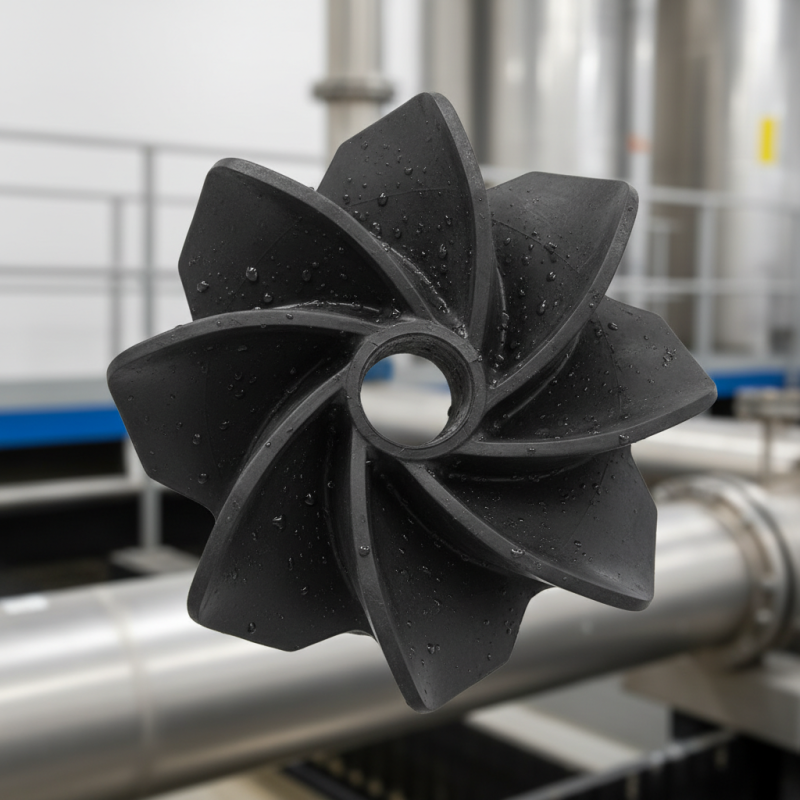

In the industrial sector, choosing the right components is critical for efficiency. The Rubber Pump Impeller stands out for its versatility and durability. According to a recent industry report, rubber impellers can enhance pump performance by 20% compared to traditional materials. This increase is crucial in applications such as water treatment and chemical processing.

Rubber Pump Impellers are not only corrosion-resistant but also provide excellent sealing capabilities. This ensures a longer lifespan and reduced maintenance costs. Industries report up to 30% fewer breakdowns when using rubber components. However, some may question their effectiveness in extreme conditions. It is essential to evaluate each application individually.

The challenge remains in understanding the ideal scenarios for rubber impellers. Over-reliance on data could lead to overlooking specific needs. As we delve deeper into the advantages of Rubber Pump Impellers, it’s vital to remain critical and reflective on choices made. Choosing the right material shapes operational success.

Benefits of Rubber Pump Impellers in Industrial Applications

Rubber pump impellers are gaining widespread attention in industrial applications. Their unique properties offer various benefits that enhance efficiency and durability. A recent report indicates that rubber impellers can reduce wear and tear by up to 30% compared to metal alternatives. This longevity translates into lower maintenance costs, making them a popular choice.

One significant advantage of rubber impellers is their resistance to corrosion and abrasion. They excel in transporting aggressive fluids without deteriorating quickly. In industries like mining and chemical processing, this resistance is crucial. However, it's essential to monitor the working environment. Extreme temperatures can affect performance, leading to potential challenges.

Tip: Regularly inspect impellers for signs of wear. Early detection can prevent costly downtime.

Another benefit is their flexibility. Rubber impellers can adapt to fluctuating fluid dynamics, maintaining efficient flow rates. This adaptability is vital for processes requiring precision. Still, operators must weigh the benefits against possible flexibility issues under certain circumstances.

Tip: Always consider your specific application. Every industrial setting has unique requirements. Selecting the right impeller can make a difference.

Key Features of Rubber Pump Impellers Compared to Other Materials

Rubber pump impellers have numerous advantages over those made from traditional materials like metal. They are lighter and can reduce the overall weight of the pump system. According to a recent industry report, rubber impellers can decrease operational noise by up to 25%. This reduction can enhance workplace safety and comfort.

Durability is another key feature of rubber impellers. They resist corrosion and chemicals better than many metals, making them ideal for various applications. In corrosive environments, rubber impellers outlast their metal counterparts, resulting in reduced maintenance costs. However, it’s important to note that they may not withstand extreme temperatures as effectively. This limitation could impact certain industrial applications, especially where heat is a major factor.

Flexibility is a hallmark of rubber pump impellers. They can absorb shock and vibrations that occur during operation, leading to smoother performance. Their efficiency can translate to energy savings, with studies showing up to a 15% increase in efficiency under certain conditions. Still, users must be aware of their specific requirements, as rubber impellers might not perform as well in high-pressure situations compared to metal options. Performance varies based on design and application, necessitating careful consideration.

Why Choose a Rubber Pump Impeller for Your Industrial Needs?

| Feature | Rubber Pump Impeller | Metal Pump Impeller | Plastic Pump Impeller |

|---|---|---|---|

| Durability | High resistance to wear and tear | Corrosion resistant, but can wear faster in abrasive conditions | Less durable, prone to cracking and degradation |

| Chemical Resistance | Excellent resistance to various chemicals | Limited resistance, susceptible to some acids | Moderate resistance depending on material type |

| Temperature Tolerance | Good, but limited at high temperatures | Excellent at high temperatures | Limited, can warp under heat |

| Weight | Lightweight, easy to handle | Heavier, requires more support | Lightweight, easy to install |

| Cost | Generally cost-effective | Often more expensive due to material | Affordable, budget-friendly option |

Applications: Where Rubber Pump Impellers Excel in Industry

Rubber pump impellers have become increasingly important in various industrial applications. Their flexibility and resilience make them suitable for handling abrasive slurries, corrosive chemicals, and varying temperatures. According to a report by Grand View Research, the global market for pump impellers is expected to reach USD 5.7 billion by 2026, with rubber components gaining significant traction.

In mining and mineral processing, rubber impellers excel in moving slurry. They reduce wear and extend lifespan compared to metal counterparts. The abrasive nature of materials like sand and mud necessitates durable materials. A study from the Mining Industry Report highlights that equipment downtime due to impeller failure can exceed 20% of operation time. Choosing rubber can mitigate such risks.

Moreover, in the food and beverage industry, rubber impellers offer unique advantages. Their resistance to various chemicals ensures safe operation in hygienic environments. However, they may struggle with extreme temperatures that some applications demand. The FDA Food Processing report notes that nearly 35% of food manufacturers have experienced equipment failures due to inadequate materials. This underlines the need for careful material selection in specific scenarios.

Maintenance and Longevity of Rubber Pump Impellers

Rubber pump impellers are known for their resilience and adaptability in various industrial applications. Their unique composition helps them withstand harsh conditions. Regular maintenance can enhance the longevity of these impellers. Inspections should be routine, especially in demanding environments. Look for signs of wear and tear. Gaps can lead to inefficiencies.

Cleaning is another critical aspect of maintenance. Accumulated debris may hinder performance. Taking a few minutes for cleaning can prevent costly downtimes. However, be careful with cleaning agents. Some chemicals might damage the rubber material. It's a balancing act that requires thoughtfulness.

While rubber impellers are durable, they are not immune to degradation. UV exposure and extreme temperatures can impact their lifespan. Regularly monitor their performance to detect early signs of failure. Adjusting operational parameters may prolong their effectiveness. Investing time and resources in maintenance is essential. It's the key to using rubber pump impellers efficiently.

Cost-effectiveness of Using Rubber Pump Impellers in Operations

Rubber pump impellers are increasingly popular in various industrial applications due to their cost-effectiveness. According to a report by the Industrial Pump Association, rubber materials can reduce operational costs by up to 30% compared to traditional metal impellers. This significant saving stems from lower manufacturing costs and reduced replacement rates. Rubber impellers are less prone to erosion and corrosion, which often plague metal parts.

In sectors like wastewater management and industrial processing, rubber impellers excel. They can handle a wide range of liquids, including abrasive and corrosive substances. Some studies note that rubber impellers can maintain performance levels for over 15,000 hours under challenging conditions. This durability translates to fewer maintenance interventions and extended pump life, providing further savings.

Energy efficiency is another vital factor. Reports suggest that rubber impellers can improve energy usage by 10% in certain applications. Essentially, these impellers can ensure consistent flow rates with less energy consumption. However, not all rubber types perform equally. Degrading in extreme temperatures is a potential concern. Companies must assess their operational environment to optimize impeller performance. Thus, while rubber impellers present notable benefits, careful selection is crucial for maximizing efficiency and reducing costs.